A new invention will face the test of commercialization

By Janis Kreilis

Last week, John Goodenough, the inventor of the lithium-ion battery that powers most consumer electronics and most electric vehicles today, announced that he, along with the University of Texas at Austin Cockrell School senior research fellow Maria Helena Braga, had invented a new type of battery that improved upon all of the characteristics of Li-ion batteries.

As described in their publication in the Energy & Environmental Science journal, the new battery cells contain at least three times as much energy per unit of volume as today’s batteries. The technology also allows recharging and discharging the battery a greater number of times, and charge them at a much higher speed. Importantly, if the technology is commercially scalable, the raw materials for the batteries should also be much cheaper.

The secret of their new invention lies in its solid state: unlike lithium-ion batteries, which rely on liquid electrolytes to move the ions between the cathode and the anode, Goodenough and Braga’s new invention uses solid glass-electrolyte. As a result, expensive and difficult to obtain lithium can be replaced by sodium which can be produced from seawater.

There are two other important characteristics the solid-glass technology promises. When charging lithium-ion batteries too fast, metal ions sometimes tend to accumulate along the electrodes, forming “dendrites,” long metal whiskers. When these grow and cross the liquid electrolyte, they short-circuit the battery and can cause an explosion. Solid glass eliminates the problem.

Another important upside is the battery’s ability to function normally at temperatures down to -4 °F (-20 °C). In fact, this is the first battery technology that functions at all below -76 °F (-60 °C).

All of these factors make them perfect for electric vehicles of tomorrow, as the new batteries would enable the cars to go further without requiring additional space for the batteries; recharge them much faster, as in minutes, not hours; function well at low temperatures; and eliminate the risk of combustion. Requiring sodium, they would also be cheaper to make and thus reduce the largest cost component in today’s electric vehicles, namely, the battery pack.

But can they be used for grid storage? After all, being able to store and later steadily release the energy generated by wind or solar, which varies throughout the day or even minute-by-minute, depending on weather, would be make integrating these resources into the grid easier. Storage could also help flatten out the demand curve and reduce the expensive peaks in demand by allowing consumers to charge their batteries from the grid at night when electricity is cheap and release it during the day when it is expensive.

Not so fast, some say. The solid-glass technology is best for the same uses where Li-ion batteries excel: where the need for high energy density makes their relatively high cost palatable. The technology has entered the U.S. residential market only recently and makes sense commercially under rather limited conditions. To store tens or hundreds of megawatt-hours required for the scale of the grid, the argument goes, would simply be too expensive using this kind of technology.

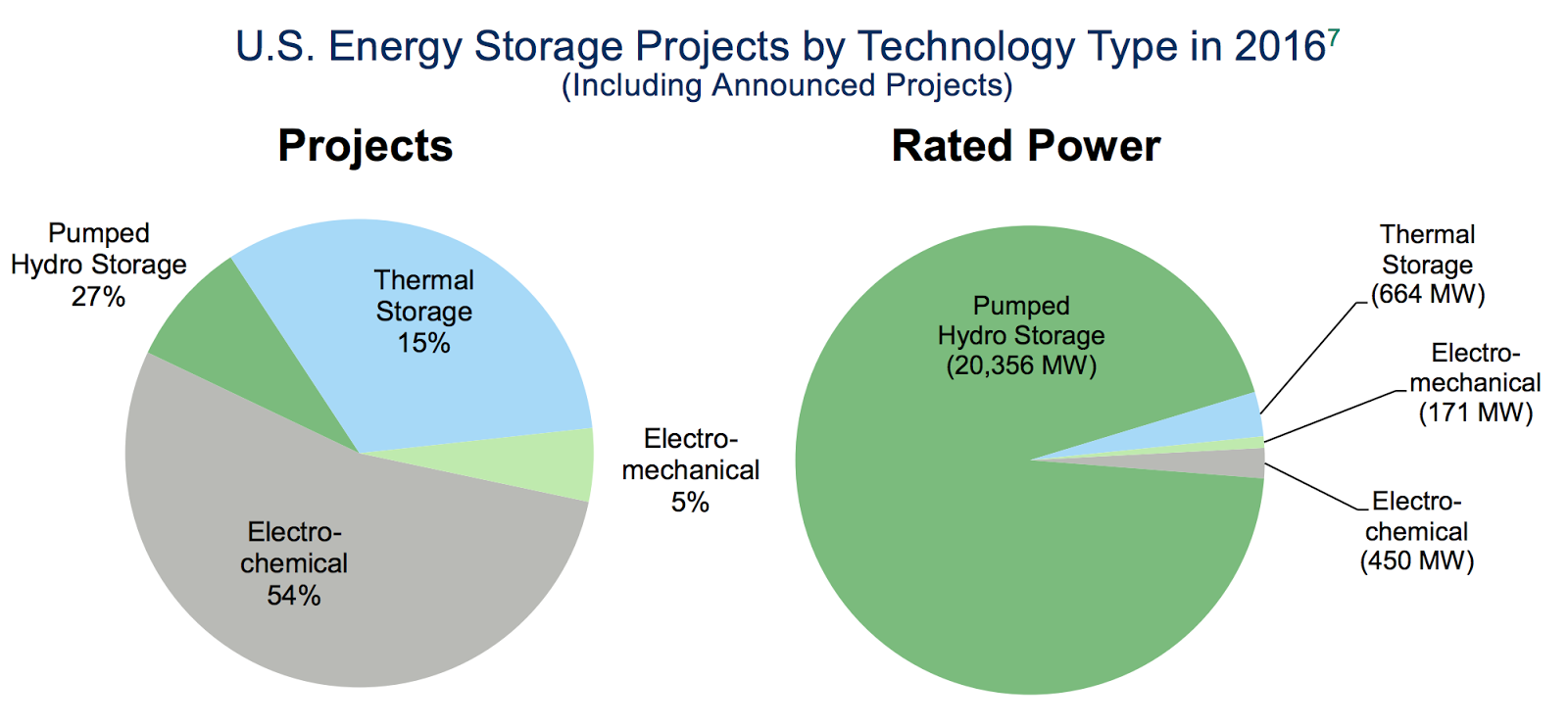

To an extent, this is true. About 95% of current grid storage in terms of rated power relies on pumped hydro, which, in simple terms, resembles a two-way hydropower station. Excess electricity is stored by pumping water uphill into a reservoir and regained later by letting the water run downhill and turn the turbines.

U.S. Energy Storage Projects by Technology Type in 2016 (Including Announced Projects). Source: DOE via University of Michigan Center of Sustainable Systems (2013)

The remaining technologies in the lead are flywheels, molten salt, and superconductors (which can store little amounts of energy but accumulate it and release it quickly making them suitable for grid balancing).

However, the picture changes when looking at the storage landscape in terms of projects planned or put in service, where electro-chemical (AKA battery) storage dominates, largely due to the small individual capacity of each project.

The cost of lithium batteries has declined steadily in recent years, and the industry has started developing several fascinating projects. For example, last year, AES Corp. began to work on the world’s largest battery storage project in California, set to replace a natural gas peaker plant in 2021. Comprising 18,000 battery modules (each the same size as the one in the Nissan Leaf), the plant marked the first time that a storage project outbid a conventional power plant when planning for the future.

If lithium-ion batteries have already proven some commercial success today (and with Tesla’s gigafactory, their costs might decline at a faster pace), then Goodenough and Braga’s new invention might turn out to be just what the grid needs – if it can pass the test of commercialization.